Rigour and expertise

Determined to establish solid, long-term business relationships with our customers, we have designed a thorough process to satisfy even their most stringent requirements. We carry out each project with rigour, professionalism, expertise and creativity.

From initial manufacturing to final delivery, our mission is to support your project every step of the way.

Production conformity

Subcontracting of CNC-machined and conventional parts

To optimize our productivity, our machining shop is designed to maximize its capacity. We have created dedicated production areas for each field of expertise.

Our expert machinists have brilliantly mastered the art of machining, whether it’s for:

- Complex, single high-precision parts

- Mass-produced parts

- Steel moulds and casts

- Punches and dies

Precision machining of parts on CNC lathes

Usinage L'Islet: Impeccable quality—guaranteed!

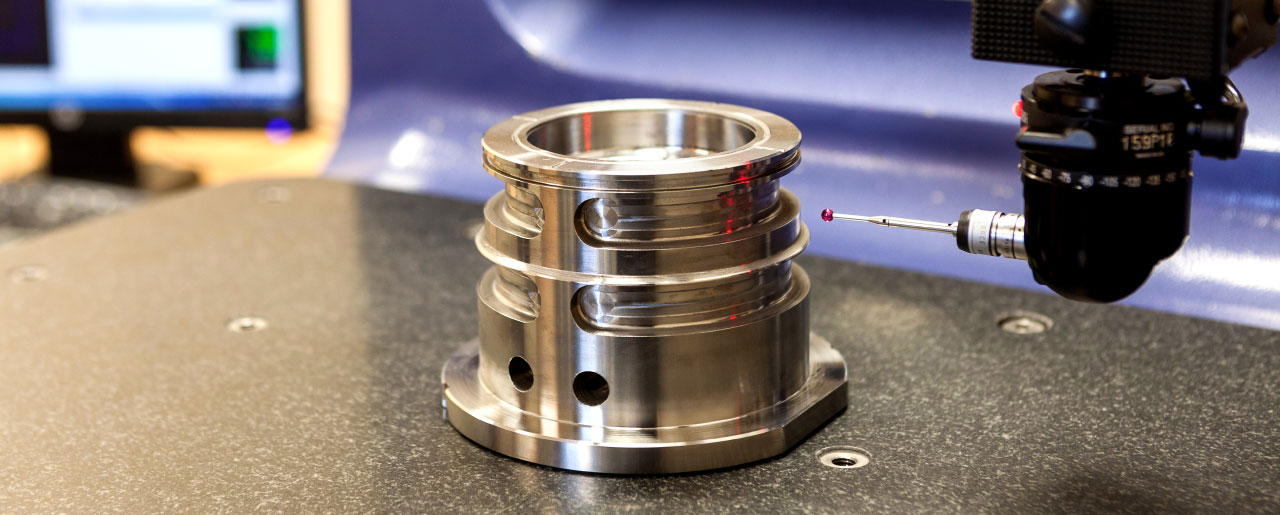

Metrology centre (CMM)

In order to ensure that all of our final products meet the highest quality standards, we perform a thorough part inspections in our metrology centre. In addition, we conduct a sample testing during production to ensure we comply with your required tolerance levels and offer you complete satisfaction.

We are relentlessly focused on meeting your requirements.

Efficiency and productivity

We continually improve our production processes to maximize our efficiency and productivity. Our specialists work hard, day in and day out, so that Usinage L'Islet remains an industry leader.

This is Usinage L'Islet’s commitment to excellence.

Machining on a 5-axes CNC milling machine

Turnkey project

From design to reality

3D design

We don’t hesitate to push the limits when designing products to suit to your needs. Our advanced 3D software enables us to visualize and simulate the extent of your project’s possibilities by putting designs to the test. Our team of draftspeople and project managers listen to your requests and remain flexible should your requirements change.

We’re synonymous with adaptability.

Learn moreAutomating high performance

Industrial equipment design

Automation projects are no secret to us. With a wealth of experience in this area, Usinage L'Islet becomes a partner in your projects, providing unmatched expertise and know-how. Our qualified designers will integrate the latest robotics and automation technology into each project they take on for maximized performance.

Together with our customers, Usinage L'Islet develops a preliminary design, assesses its feasibility and oversees its development. We assist the customer every step of the way.

What’s more, we advise you about the products to use in order to comply with the CSST’s safety standards. Constantly seeking new ways to ensure safety, Usinage L'Islet’s objective is to protect workers—all while maintaining the company’s productivity.

A close relationship with our customers is essential for us.

Learn moreDesign and development of a quality-control inspection system

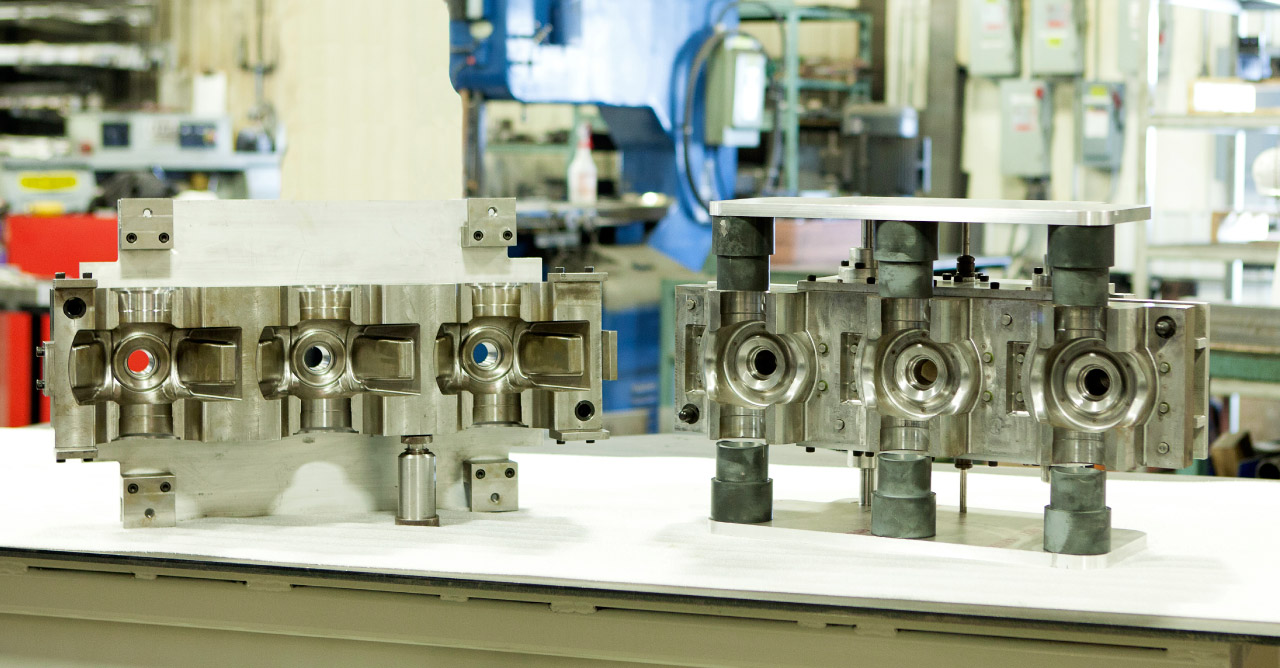

Foundry moulds and casts

Over the years, Usinage L'Islet has amassed a wealth of expertise in the design and production of accurate moulds and casts.

A know-how that makes us stand-out

Learn more

Conventional services and welding

In order to provide you with the most reliable and robust products, Usinage L'Islet insists on using the best welding and assembly methods available. In fact, we use the following welding processes: FCAW, CMAW, GTAW, OAW and SMAW. Whether for soft steel, alloys, aluminum, stainless steel or cast iron, our jobs will be without burrs and made to last.

Count on us.